Fuel Additive Injection

Application-Related Downloads

Application Summary

Application

Fuel Additive Injection

Description

Improving or changing fuel performance by injecting fuel additives

How It’s Used

Pumping a wide variety of fuel additives, at a constant, controlled flow rate, into an injection manifold to facilitate mixing during fuel dispense

Key Feature

Chemical resistant pump materials

End Equipment

Fuel dispensing equipment

Pump Function

Metering

Fluids

Corrosion inhibitors, lubricants, anti-icing additives, dyes, detergents, static dissipating additives

Flow Rate

0.5 to 10 L/min (7.9 to 159 USG/hr)

Differential Pressure

<40 psi (<2.76 bar)

Applications Overview

Fuel can be improved, changed or enhanced through the addition of fuel additives according to specific performance and usage requirements.

Additives can be added at the rack in a distribution terminal, at a service station style dispenser, or into the fuel stream dispensed from a delivery truck.

Typical examples include:

- Refining additives

- Detergent additives to keep fuel injectors clean

- Color dyes to identify fuel grades

- Lead-based additives for aviation

- Corrosion inhibitors

- Lubricants for extended engine and pump life

- Anti-icing additives for jet fuel

- Static dissipater additives

Micropump pumps deliver smooth, controlled flows of fuel additive into a fuel dispensing system.

PUMPING REQUIREMENTS

MICROPUMP SOLUTIONS

FLOW RATE: 0.5 to 10 L/min (7.925 to 158.5 USG/hr)

We have variable speed pumps for this application with flows from 0.131 to 13.9 L/min (2.1 to 221 USG/hr)

CHEMICAL RESISTANT TO HYDROCARBONS

Our chemically resistant construction materials stand up to the aggressive fluids found in fuel additives

PRECISE, METERED FLOW CONTROL

Our gear pumps with variable speed DC drives provide precise flow control

SMOOTH, PULSELESS FLOW

Gear pumps offer the virtually pulseless flow required for in-flow additive dispense

RELIABILITY

Our precision design and manufactured gears stand the test of rugged use

LEAK FREE

Our magnetic drives eliminates dynamic shaft seals, keeping fluid securely inside the pump and potential contaminants out

MAINTAINABILITY

We offer Service Kits for easy field serviceability

Performance Summary

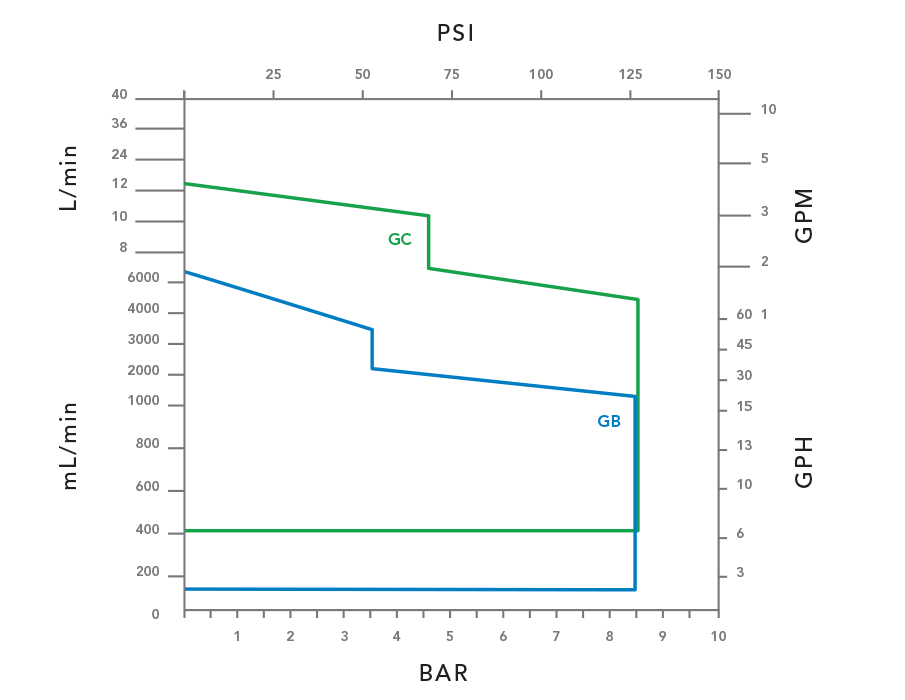

This chart indicates optimal operating ranges for recommended products.

Micropump Products Optimized for this Application

Micropump “suction shoe” style pumps are commonly used for this application. Series GB are best suited for lower flows, and Series GC for higher flows. Suction Shoe style gear pumps provide more consistent flow with varying differential pressure, and extended pump wear, than standard cavity style gear pumps. Suction shoe pumps also perform better with wide ranging temperature changes than cavity style pumps. Our integrated electromagnet EagleDrive™ provides variable, precise flow control in an energy efficient and compact package.

The Micropump Advantage

The unparalleled quality, performance record, reliability and long operating life of Micropump pumps and our extensive engineering expertise make Micropump a vital partner in this demanding market.

Headquarters

1402 NE 136th Avenue

Vancouver, WA 98684-0818 USA