Pulp & Paper Bleaching

Application-Related Downloads

Application Summary

Application

Pulp & Paper Bleaching

Description

Wood pulp bleaching to attain the desired level of paper whiteness

How It’s Used

Pump bleaching agents into mixing towers to maintain correction solution

Key Feature

Chemical resistant pump materials

End Equipment

Paper pulp bleaching equipment

Pump Function

Dosing

Fluids

Hydrogen Peroxide

Flow Rate

50 mL/min (0.79 USG/hr) to 19L/min (300 USG/hr) flow rates

Differential Pressure

<40 psi (<2.76 bar)

Applications Overview

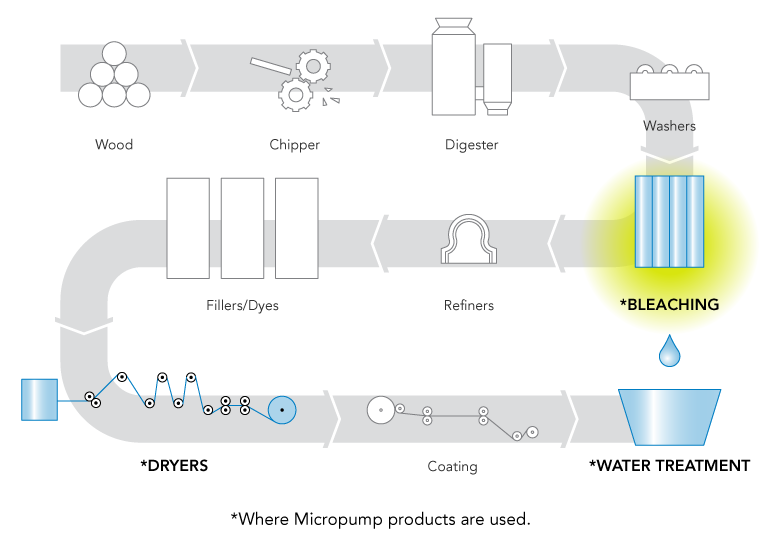

Pulp & Paper Manufacturing Process

The following illustration is an overview of the entire Pulp & Paper manufacturing process. Notice that Micropump pumps have application in three of the process steps. This application brief focuses on the application of Micropump pumps in the Bleaching process step.

Application Focus: Bleaching

In the paper manufacturing process, wood pulp leaving the digester wash unit often must be bleached to attain the desired level of paper whiteness. Bleach plants whiten pulp through three to five stages of bleaching and water washing.

Micropump pumps are used in these applications to deliver the appropriate bleaching agent and to maintain the proper chemical balance in the bleaching towers.

Micropump pumps deliver smooth, controlled flow of whitening agents to the bleaching towers.

PUMPING REQUIREMENTS

MICROPUMP SOLUTIONS

FLOW RATE: 0.050 to 18.9 L/min (0.79 to 300 USG/hr) flow rates

We have variable speed pumps with flows from 0.158 to 42.9L/min (2.5 to 680 USG/hr)

CHEMICAL RESISTANT PUMP MATERIALS

Our pump construction materials stand up to most pulp bleaching chemicals

PRECISE FLOW CONTROL

We offer positive displacement gear pumps for precise metering of bleaching agents

LEAK-FREE OPERATION

Our pumps have magnetic drives, so no shafts penetrate the pump cavity, eliminating leak-prone dynamic shaft seals

MAINTAINABILITY

We offer Service Kits for easy field serviceability

Performance Summary

This chart indicates optimal operating ranges for recommended products.

Micropump Products Optimized for this Application

Micropump cavity style pumps are commonly used for this application. All pump base materials are 316 SS with PTFE wetted materials.

The Micropump Advantage

The unparalleled quality, performance record, reliability and long operating life of Micropump pumps and our extensive engineering expertise make Micropump a vital partner in this demanding market.

Headquarters

1402 NE 136th Avenue

Vancouver, WA 98684-0818 USA